Chunlong Planetary Gearbox features in compact structure, little size, light weight, low noise, high carrying ability and steadier meshing, the material of which is LC alloy steel, After carburizing and quenching technique, the surface of gear is harsh while the core is tough, Internationally advanced equipment also ensures high quality.

Serialization of planetary gearbox has been achieved to output torque as needed and to fit brands of servo motor.

Model:GJSQ120P;Reduction Ratio(Nin/Nout):58.13;Output Torque Range(N.m):500-1000;Coordinated Servo Motor Power(kW):3.0;

Model:GJSQ100;Reduction Ratio(Nin/Nout):48.29;Output Torque Range(N.m):230-700;Coordinated Servo Motor Power(kW):1-2.5;

Model:GJSQ80 ;Reduction Ratio(Nin/Nout):54.08 ;Output Torque Range(N.m):130-210 ;Coordinated Servo Motor Power(kW):0.75;

Model:GJSQ60 ;Reduction Ratio(Nin/Nout):44.80 ;Output Torque Range(N.m):60-105 ;Coordinated Servo Motor Power(kW):0.4 ;

Model:GJSQ60P ;Reduction Ratio(Nin/Nout):50.80 ;Output Torque Range(N.m):60-120 ;Coordinated Servo Motor Power(kW):0.4 ;

Model:JSQ200A ;Reduction Ratio(Nin/Nout):118.00 ;Output Torque Range(N.m):153 ;Coordinated Servo Motor Power(kW):0.4 ;

Model:JSQ10 ;Reduction Ratio(Nin/Nout):41.50 ;Output Torque Range(N.m):53 ;Coordinated Servo Motor Power(kW):0.4 ;

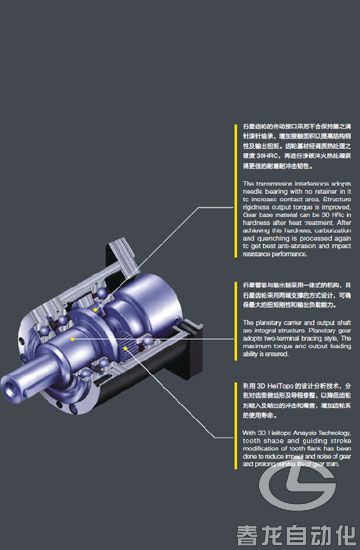

The transmission interference adopts needle bearing with no retainer in it to increase contact area, Structure

rigidness output torque is improved, Gear base material can be 30 HRc in hardness after heat treatment, After

achieving this hardness, carburization and quenching is processed again to get best anti-abrasion and impact

resistance performance.

The planetary carrier and output shaftare integral structure, Planetary gearadopts two-terminal bracing style, The

maximum torque and output loadingability is ensured.

With 3D Helitopo Analysis Technology, tooth shape and guiding stroke modification of tooth flank has been

done to reduce impact and noise of gear and prolong service life of gear train.