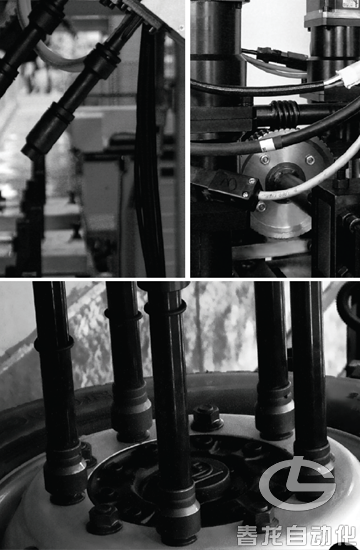

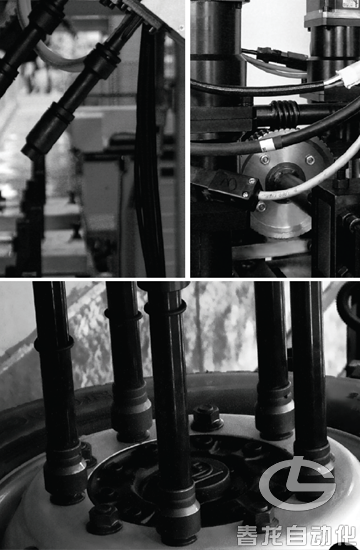

There are horizontal type, vertical type, tilting type and machine tool type in operation mold.

Horizontal type: Output Motive Power is in horizontal direction, suitable for tyre bolt tightening position of various vehicles.

Vertical type: Tightening Machine is suspended above work position to save space, often applied in Axle U Bolt Tightening work position.

It can be divided into hand and automatic shift according to shift type.

Manual shift center distance : Center distance modification handle moves shift screw rod of tightening shaft, driving screw with thread to drag planker to move along guide slot of bottom plate. It is easy and reliable. Center distance modification time is less than 60 seconds.

Automatic shift center distance: Cylinder or servo motor drives guide bushing to realize center distance modification within 5 seconds.

It can be divided into single shaft,two shafts, three shafts, four shafts……. eighteen shafts and multiple shafts

according to shaft quantity.