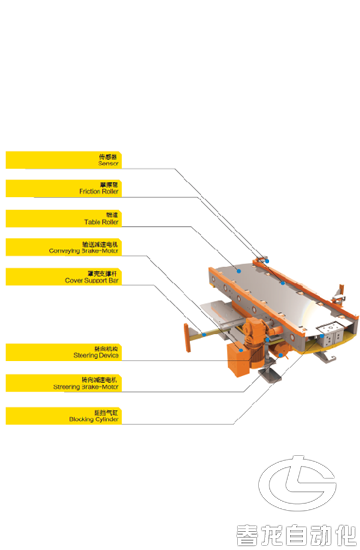

Rotary Table

∷ Main Components

It is to make workpieces move along assembly line direction when they come to intersection angle or turning

position.

∷ Main Function

IIt is to make workpieces move along assembly line direction when they come to intersection angle or turning

position.

∷ Process

Roller bed on rotary table runs automatically when workpieces reach rotary table. Blocking cylinder ascends

automatically too. After workpieces are in place, roller bed breaks down and steering motor starts. Rotary table is set in rotating motion by gear mechanism. Steering motor stops when workpieces reach intersection. Meanwhile,conveying motor starts to deliver workpieces to next station.Finally, steering motor reverses and rotary table switch back to original position. The turning speed of rotary speed and conveying speed of roller bed are adjusted by frequency converter of corresponding motor. The turning angle of rotary table is adjustable by regulating the limit sensor position.